Handmade in the uk

Handmade in the uk

Aston Martin DB2/4 Mk3 Aluminium Front Grille Surround

New- DB2/4 Mk3

Aluminium grille surrounds fit and attach around the bonnet’s grille aperture on the DB2 Mk3 models. DMark® offer two variants, our new and improved version which is best matched with our new grille meshes, and a tabbed version that matches the factory configuration that will allow old meshes to be attached.

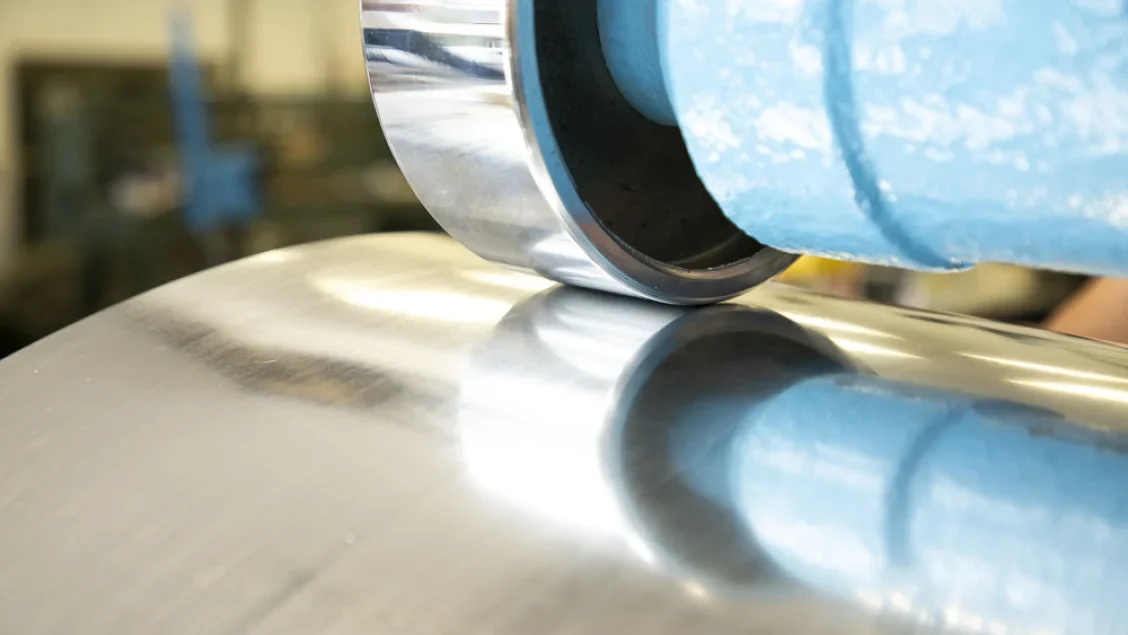

Fitted directly to the aperture bodywork via ten tabs/fixing points, our surrounds have a polished profile edge (the visible profile lip) which is left as-is in bare metal.

This grille shape precedes the horizontal slatted grille of earlier models and is made using our own DMark® custom tooling, jigs, patterns and aids.

This DMark® DB2/4 Mk3 grille surround is finished with a polished aluminium surface around the visible rim with all other areas left naturally brushed. This part is not chrome plated.

For the most part, these our aluminium surrounds are Made-to-Order.

A series of brackets and fasteners is supplied with each surround.

Customers will be aware that, in particular, when vehicles have had extensive repairs; their bodywork, paintwork and the extent of body-filler used can change the panel-shape of the zone mouldings are meant to sit. At DMark® we have taken great care to replicate the most original shape known but occasionally that may differ from the surface geometry of a vehicle. A similar scenario could also mean stud holes in the bodywork may differ to the stud and fixing positions of new DMark® parts.

The aluminium grille edge profile surround that encapsulates the edge of the bodywork around the perimeter of the bonnet’s grille opening. The grille mesh is also attached to this part from within the engine bay.

This variant comes with 10 tabs, and replicates the factory specification, which allow for the mesh to be mounted through. Tabs are pre-drilled but can be left blank if requested by the customer.

Grille Surround Bracketry

This aluminium surround type comes supplied with 10 simple right-angle brackets with nutserts that are attached to the bodywork and hold the aluminium surround in place.

We’ve seen them either welded or riveted to the aperture’s rim.

The surround is then fixed into position by screwing into the bracket’s nutserts through the holes in the surround itself.

Each bracket will need to be trimmed and tailored to the car. Some vehicles may not need new bracketry, but we do see cars that ought to have these things tidied up to accomplish the optimum fit.

Our new DMark® surround variant pairs best with our new grille meshes. The main difference over the tabbed version is the absence of the ten large tabs. The shape and aluminium profile is the same.

Instead our new variant includes threaded nutserts – where holes used to exist – that enables the mesh to be fitted (and removed) far more easily. It still encapsulates the edge of the bodywork around the perimeter of the bonnet’s grille opening as normal, so there is no visible difference.

Our new grille meshes are fitted by screwing directly into the surround’s nutserts rather than having to fiddle about with a nut in a very confined area.

DB2/4 Mk3 grille meshes by DMark® have a newy perimeter configured pattern that allows for the surround’s own fixturing to the bodywork which is why they’re ideally paired.

Grille Surround Bracketry

This aluminium surround type comes supplied with 10 simple right-angle brackets with nutserts that are attached to the bodywork and hold the aluminium surround in place.

We’ve seen them either welded or riveted to the aperture’s rim.

The surround is then fixed into position by screwing into the bracket’s nutserts through the holes in the surround itself.

Each bracket will need to be trimmed and tailored to the car. Some vehicles may not need new bracketry, but we do see cars that ought to have these things tidied up to accomplish the optimum fit.