Our Capabilities

Deep and wide proficiency for any metalworking requirement. We can provide proven, comprehensive skills across the metalworking disciplines to help you realise your creative vision – however complex or ambitious.

It doesn’t even have to be fully defined at first. If it’s physically possible, DMark is one of an elite few metalworkers that can provide in-depth consultation support alongside mastery in fabrication.

test

tester

Metalworking

Metalworking is a broad church, but is perhaps the best way to define the comprehensive combination of skills we provide. Ultimately, we’re dedicated metal fabricators, but decades of in-depth experience inform our trusted consultation services for complex projects.

Our experience also enables us to work from old-school drawings as well as modern software – we’ve been mindful to embrace technological advances, without losing sight of the traditional design techniques and formats. And while we provide a vast range and combination of processes at our primary workshop, we also maintain a remarkable network of complementary craftspeople and associated experts.

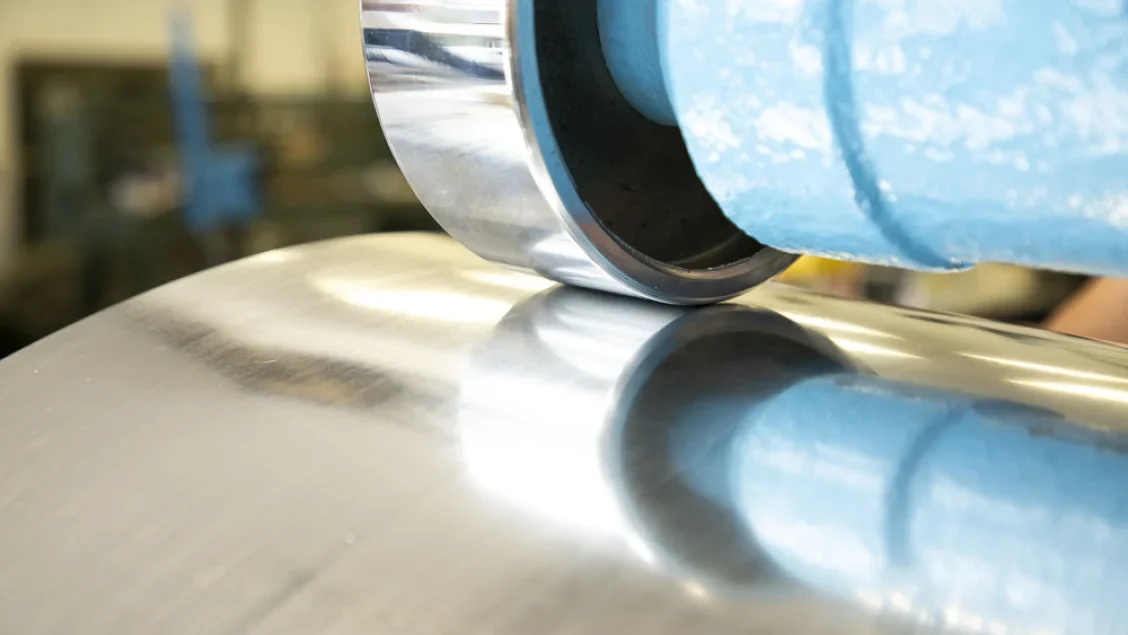

Metal forming

This entails fashioning metal parts and objects into myriad shapes and forms, through precision mechanical or hand-deformation. It demands a deep and long-standing working knowledge of different metals’ strengths and malleability, and our generation-spanning experience has informed our unique ‘adaptive approach’.

This combines modern techniques, technologies and tooling with proven traditional methods that are increasingly difficult to source – and are rarely integrated in this way, to such effect.

caption here

description here

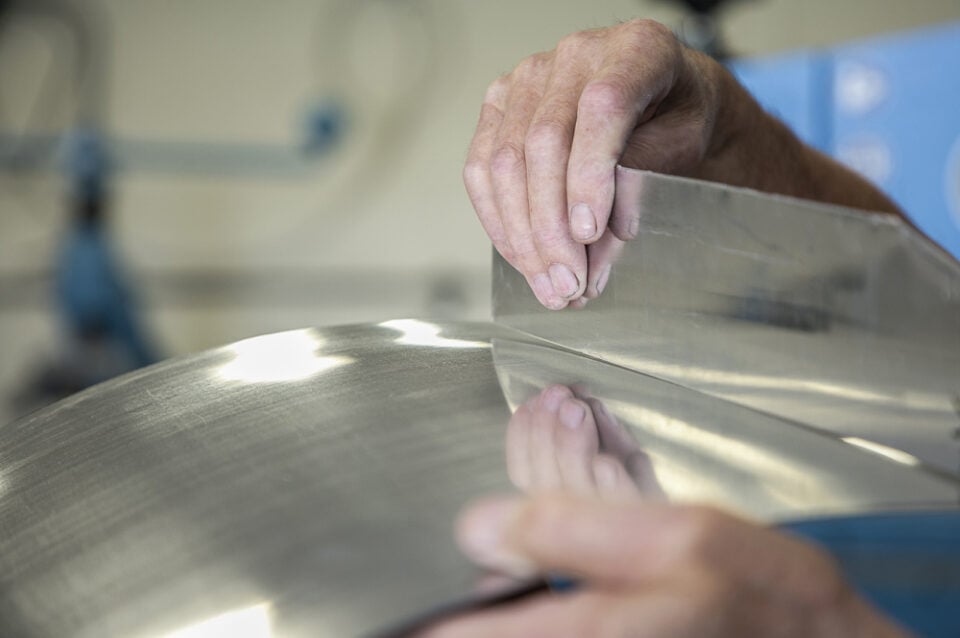

Fine Metal Finishing

DMark’s renowned high standards for metal finishing require an almost fanatical dedication and attention to detail. But it’s worth it, for a consistent and flawless finish that’s fit for the closest of scrutiny, and suitable for an art gallery.

We can provide for unlimited variations and subtle variants, and either create to the final finished surface or prepare for further procedures and processes. Whatever means the best possible end result…

Complex Metalwork

We love to help realise bespoke, extraordinary and ambitious visions in sheet metal. Our depth and breadth of knowledge and experience means we can think laterally and identify solutions to even the most difficult and fanciful briefs – and step in when a project’s scope or complexity has been ill-defined… or grossly underestimated!

Bespoke metalwork is our life, and we use a blend of modern and traditional fabrication techniques to realise some pretty outrageous concepts. Non-uniform shapes, with all manner of sweeps, curves and straight lines, are where our knowledge can become invaluable. We aim for the exceptional, and if anyone can identify, explain and implement the best way to achieve it… we can.

Panel Making

Panels are a core component of many of our projects, and we know precisely how multiple forms can come together seamlessly to form larger pieces – whether it’s wall art, installations, sculptures, or vintage car bodywork.

We expertly create custom panels as individual items or batches, depending on the need, and extend our skills to alignment and fit, fixing panels together with care and precision.

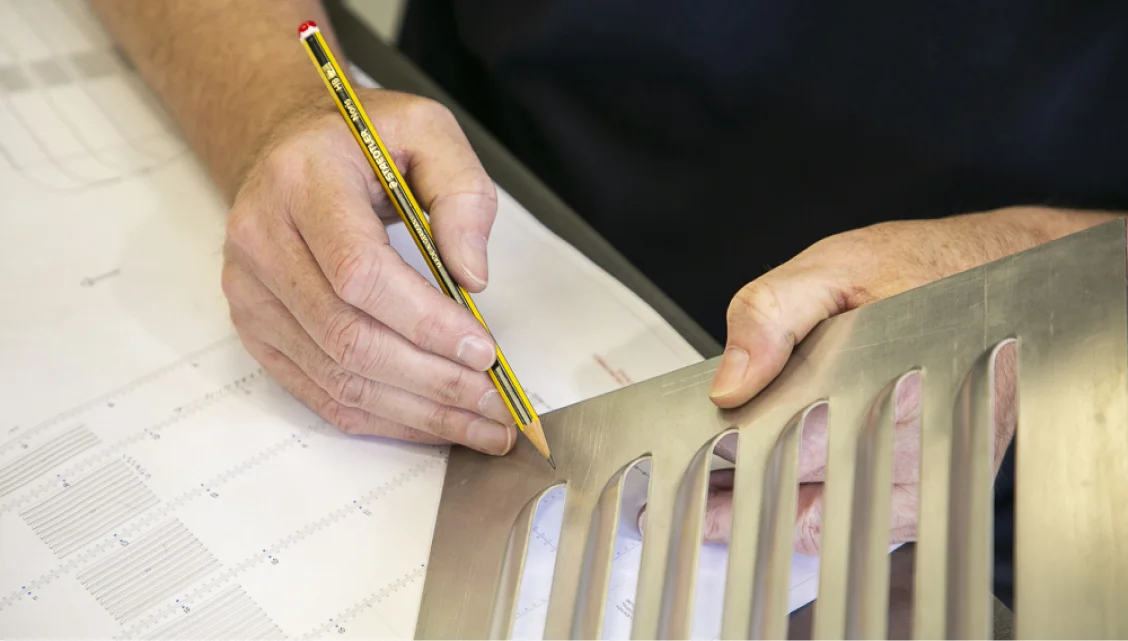

Louvres

DMark has decades of experience creating bespoke louvres for cars, whether for cooling or purely aesthetic purposes – or for a stylish and functional combination of the two. We’ve worked with some of the world’s most prestigious collections, owners, enthusiasts and aficionados, to create or recreate works for cars.

Using our very own in-house deep throat fly-press, along with custom tooling, we can create louvres in sheet metal as part of head-turning works of art, whatever their function.

Fabrication by hand

The vast majority of our metalwork is by hand, and over many years this is perhaps what’s taught us most about various metals’ characteristics, behaviours and limitations.

We believe handicraft is fundamentally different to machine work, but we’re adept with both, and understand they complement each other. By hand, we have greater creative control and precision with freeform joins and edges, and with delicate alterations. Handmade fabrication is a fundamental aspect of most of our projects.

Coachbuilding

Our roots in coachbuilding are well documented – as is Don’s involvement in building and modifying custom bodywork for high-end marque sports and vintage cars throughout the 1980s and 90s.

Often comprising metal-panel cladding over timber, panel-making and tailoring with the emphasis on the fit, we employ coachbuilding techniques across much of our work. We also combine many traditional coachbuilding processes in our brass brightwork and fixtures products.

Double Curvatures and Multiformed Shapes

To create truly extraordinary work in metal, you need to be able to create a multitude of shapes and sizes with skill and confidence. Over several decades, we’ve developed a rare flair for realising intricate and spectacular visions, helping many customers bring ambitious projects to life.

This can be the most challenging work we undertake, but it’s the kind of work we relish, and it’s often the most rewarding. We can combine metals, create seamless transitions between textures, and achieve subtle changes in form, shape and direction.

Sheet Metalwork

This is often where a project starts – and where skill, experience and precision can dictate the ultimate outcome. We’ve got to know sheet metal intimately over many years of practical application, and we always relish the opportunity to turn a flat sheet into a complex, aesthetic form.

Our expertise encompasses aluminium, bronze, gilding metal, brass, copper and zinc, as well as steel and stainless steel, and we understand the properties and possibilities that each presents.

Consultancy

Our proven and profound experience in metalwork means we can share deep and invaluable insights to support even the largest and most audacious of projects. We’re open and generous with our knowledge, and we’re happy to assess and evaluate the complexity and viability of your plans.

Early-stage scoping with DMark can mitigate the risk of project lag and creep significantly, and ensure you avoid overspend or potential project abandonment. It can also help you identify alternative design or fabrication strategies long before your initial approaches become prohibitively urgent and/or expensive.

In short, our technical appraisals and strategy assessments essentially audit a project’s viability within the brief’s parameters, and cover all technical aspects plus considerations for handling, storage, transportation and installation.